A turbocharger reconditioning is an essential procedure to the automotive performance tuning reality. Whether you are a car enthusiast dreaming to increase the vehicle’s power or a mechanic who desires to provide sublime after service. The importance of knowing the physics of turbo reconditioning cannot be overrated. We are going to take a look at the process of turbo recondition in this guide. It is very nice to go into detail about issues. Why turbo reconditioning is necessary, the steps that you need to follow and the benefits.

What is Turbo Reconditioning?

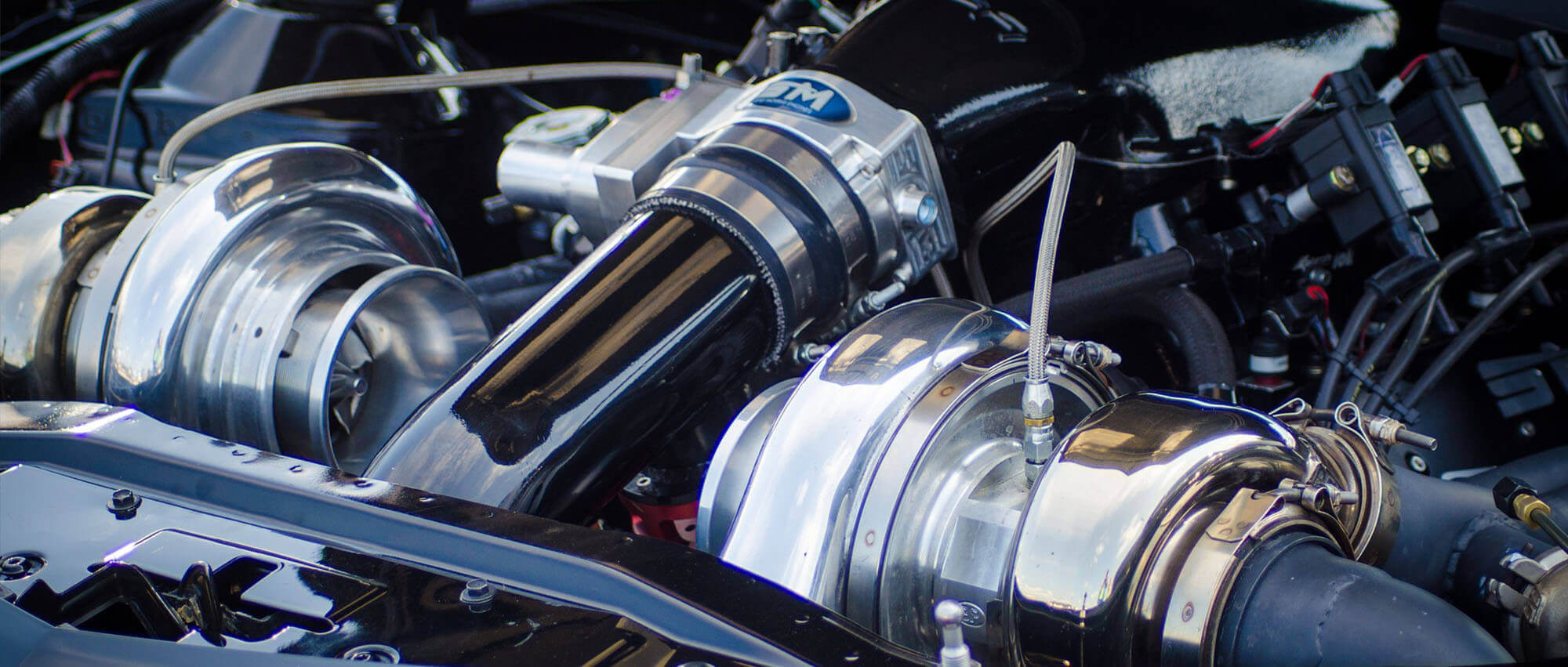

In this context, remanufacturing of turbo involving the process of refurbishment will help restore the working life of the turbocharger. Once again to the best performance and efficiency along with the least possible emission. Among the key units in the modern engine, one is the turbocharger which is used to increase the air pressure to compress it to a dense state. Before passing the gas flow through the combustion chamber. Secondly, a boosted car is rather sturdier, effective and energy-efficient. Which is a big relief to the drivers who are concerned about response effect.

Configuring a silo such as this requires extensive engineering, technical expertise, and careful consideration of a variety of factors. These can include dimensions of the silo. The strength of the walls and roof. The material of construction. The mode of unloading and the appropriateness of its site location. The abrasion may lead to worn down. Increasing fuel consumption, and can as well continue to damage the engine if the problem persists.

The Priority and Deterrence of Turbo Reconditioning

Restoring Performance: The principal cause of turbo recondition is to get the turbocharger back to an operational level again. Rust lichen can be eliminated by changing worn-out elements; internal corridors can be cleaned, and assembly can be made correctly. As a result, the power and torque can be regained.

Preventing Damage: A damage prone or unkept turbocharger can come with lots of hindrance to the engine. Retrofitting of combustion engines helps reducing oil leakS. Potentially damaging the turbine or compressor. The excessive exhaust fumes emissions, hence increases the lifespan of the motor.

Improving Efficiency: The increased overall performance of the forged turbocharger occurs when the high fuel economy and low exhaust outflow. In view of this, it can be concluded that this is a crucial issue. This influences modern automotive industry models. This pay attention to environmental issues and fuel efficiency standards.

The Turbo Reconditioning Process

Initial Inspection: This process commences by conducting a comprehensive turbocharger inspection aimed at determining the status of the item and detecting its problems. It entails application of techniques like leakage check of oil, discovering if the turbine blades and compressors are damaged. Assessing the conditions of waste and actuator system.

Disassembly: The turbocharger is then unscrewed millimeter by millimeter. Each part is cleaned individually. To gather defective or damaged such as the bearings, seals, and gaskets. High-quality spares are bought and continually replaced to guarantee achieving the desired performance.

Cleaning and Machining: Coming from, and the cleanliness of, the internal components, compressor and turbine casings, are done by means of special equipment and procedures. Here, at layer or filter level. We will remove items such as carbon deposit, oil mist and contaminants. These will cause further problems in the future. This may include machining to restore the original monitoring clearances and tolerances.

Machining May be also Needed

Reassembly and Balancing: There are those processes that clean the components and inspect them. The turbocharger is reassembled to manufacturer specifications. Balancing compressor and turbine wheels to the precision required is a crucial measure. Taken in order to suppress vibrations and ensure that the operation of the machine is smooth.

Testing: Reconditioned turbo unit goes through anti-fail tests. These Tests ocused on the adherence to the same set of features which were presented in the brand-new turbo. These comprise exploration of peak boost air intake pressure, oil flow and their system efficiencies. It will be the only thing that will succeed these tests that will make the turbocharger ready for the installation.

Benefits of Turbo Reconditioning

Cost-Effective: The process of the turbocharger reconditioning is sometimes cheaper than the purchase of a new unit. Which is better in cases of overall and/or some precise applications.

Improved Performance: Most of the time, regeneration of a worn-out turbocharger can bring back its earlier performance. Give an engine not less than enough power and torque.

Extended Lifespan: Rightly reconditioned turbochargers can move long miles without repetition which means less replacements inquire and thus cutting on the cost.

Environmental Impact: Engine efficiency is one of the targets that turbo reconditioning services help to achieve with the additional benefit of reducing automotive emissions, which are known to contaminate the atmosphere, making the automotive industry greener.

Conclusion

It is in the turbocompressor reconditioning, that the turbocharged engine enjoys the maintenance and upgrading enhancement. Global warming and weather extremes are just two of the many benefits that reconditioning has. These include the ability to restore lost power or to prevent massive damage in the engine system in time.

Through very good screening, examination, dismantling, washing, and fixing – turbochargers can be revived and run for miles propelling your run at their optimum performances. Even among the fans or professionals regardless of the level of turbo upgrade it is the sense of the significance of the turbo charge which assists car engines to perform up to their highest capability.

FAQS

What is Turbo Reconditioning?

Remanufactured of a turbocharger is undergoing the rebuilding process to change the worn-out turbo parts in order to make the turbocharger operate in the manner it was first designed to function. The technician gets to the turbocharger in two stages; one, he dismantles the internal components; two, he cleans, replaces worn or damaged components, assembles those back and in the end, carries out inspection to ensure the system is working as it should.

Besides the fact that Turbo Reconditioning is Critical, Why is it necessary?

The turbo reconditioning is significant because it is aimed at the lost performance’s restoration, the engine’s protection, the efficiency increasing, and, finally, the longevity forcing the turbo system. The oil and filter change will consequently help maintain a perfect condition in which your car will run smoothly and perform well.

The frequency intervals for turbochargers reconditioning is an issue.

Reconditioning of turbocharger frequencies will be triggered by different factors. Driving habits and maintenance practices will be some of the major triggering factors. Furthermore, turbocharger quality will also be a key aspect. In most cases, it is recommended to do regular checks at least once in every 50,000 to 100,000 miles that a vehicle is driven, which may include reconditioning the turbocharger also as recommended by the manufacturer.

What are the indicative factors that tell us it is the time to have a turbocharger reconditioned?

Comprehensive inspections are always recommended before the reconditioning of an engine turbocharger. The common signs that indicate an engine turbocharger requires reconditioning are reduced power and acceleration, increased fuel consumption, smoke from exhaust, unusual noises (such as whining and grinding), and engine oil leaks around the turbocharger.

Could I do a turbocharger tune-up/repair at home?

Turbocharger re-engineering necessitates the possessing of the expertise and equipment that is high-tech and requires tools. Turbochargers should be reconditioned so that it is best done by someone well-trained or at least a certified mechanic who knows what they’re doing when working on such a complex system.